The mould

First we make a mould. The mould

determines the internal shape of

the product.

Heating the mould

The mould is preheated in

an oven.

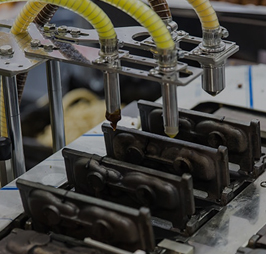

Dipping in liquid vinyl/plastisol

The mould is attached to a special

frame and then dipped in a bath of

liquid vinyl/plastisol.